The tundish is the last container in the continuous casting system where the molten steel contacts the refractory material before it is formed. It is an important part of the continuous casting process and has a great impact on the quality of steel. With the advancement of smelting technology and the emergence of ladle secondary refining technology, the tundish has many important functions, such as providing a stable static pressure of the molten steel, maintaining the stability of the molten steel flow rate and flow, reducing turbulence, removing non-metallic inclusions in the molten steel, purifying the molten steel, and keeping the molten steel temperature basically unchanged. It has become a molten steel refining container before the molten steel is formed. With the increase of the functions of the tundish, the variety of refractory materials used in the tundish has increased, and the quality requirements for refractory materials have become higher and higher.

Development History of Tundish Lining Refractory Materials

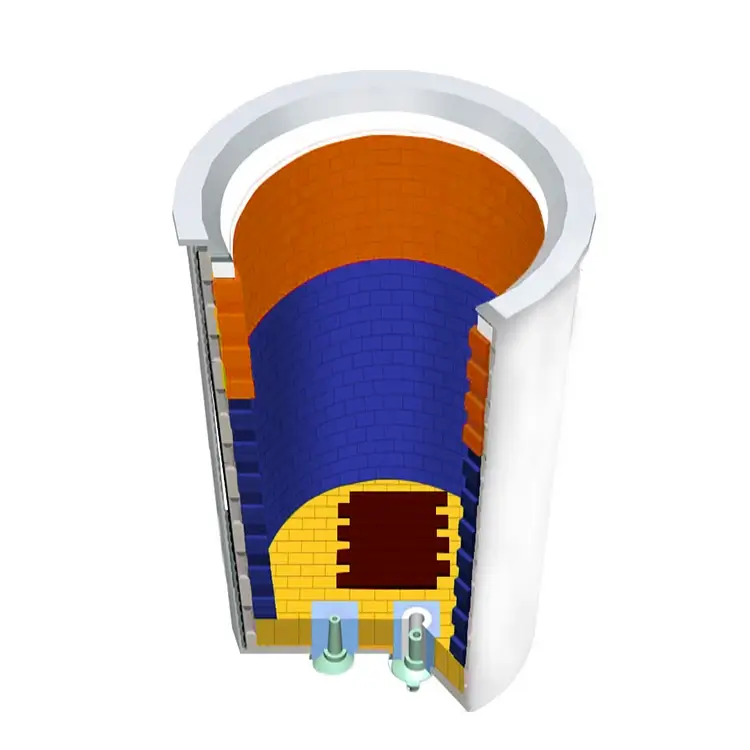

The traditional lining of the tundish is mainly composed of permanent lining and working lining, and its refractory materials are light bricks, heavy bricks, insulation boards, coatings and dry materials. Traditional permanent linings are all built with refractory bricks. Due to the many brick joints and poor integrity, it is easy to cause piercing accidents. In recent years, with the successful application of integral casting technology on ladles, the permanent lining of the tundish also uses castables or ramming materials of amorphous refractory materials. The development of the working lining of the continuous casting tundish in my country is roughly as follows:

Silica insulation board period: From the introduction of continuous casting technology in the 1980s to 1995, the working lining of the tundish mainly used silica insulation boards. Its main raw material is quartz sand, adding a part of paper scraps, combining with powdered thermoplastic phenolic resin and urotropine, vacuum suction filtration molding, drying and use, the average service life is about 6h, and the maximum is no more than about 10h. Silica insulation boards have a low service life, poor corrosion resistance, and pollution to molten steel. Since 1995, they have been gradually replaced by magnesium or magnesium-calcium coatings.

Magnesium or magnesium calcium coating period: Before 2000, my country’s continuous casting tundish working lining generally used magnesium or magnesium calcium coating, which was applied on the surface of the permanent lining of the tundish, and the thickness was generally 35mm~40mm. This type of alkaline coating is usually prepared by sintering or electro-melting magnesia sand or magnesium calcium sand. However, since magnesium calcium sand is easily hydrated, raw dolomite can be used to introduce CaO or anti-hydration magnesium calcium sand and magnesium sand can be mixed in a certain proportion. The critical particle diameter of the coating is 3mm~5mm, and the particles with a diameter greater than 0.088mm account for about 60%~65%, and the particles with a diameter less than 0.088mm account for about 35%~40%. Organic fiber accounts for about 0.5%~2.5% (short fibers processed from natural plants are better). As the amount of fiber added increases, the volume density decreases, and it is generally better to control it at 1.9%~2.3%. The main admixtures are plasticizers, such as soft clay, bentonite, silica powder, slaked lime, etc., which also play a sintering role. The higher the CaO content of the tundish lining, the better it is at purifying molten steel. However, it is difficult to prepare a coating with a high CaO content, and the CaO content of the coating is generally between 10% and 50%.

Forsterite is used to replace magnesia to produce tundish coating. Forsterite has low thermal conductivity, high refractoriness, no hydration, good chemical stability, good resistance to metal melt penetration, and its resources are abundant and widely distributed, which is both energy-saving and environmentally friendly and can reduce costs. The formula of forsterite tundish coating produced by Xinjiang Bayi Steel Plant is: forsterite 40% (2.5mm~0.5mm), medium-grade sintered magnesia 48% (0.5mm~0.088mm), lightly burned magnesium oxide powder 5% (<0.088mm), plus magnesium sulfate heptahydrate 2.5%, paper fiber 2%, borax and explosion-proof fiber 0.1% each, which can be adjusted appropriately according to different seasons. The amount of water added is about 25%, and it is applied manually with good adhesion. The service life of this coating is equivalent to that of magnesium coating, which can reach 10h~14h. Its thermal insulation performance is better than that of magnesium coating. When turning the bag after use, it is easy to separate from the permanent lining.

Wet alkaline spray coating: Generally, it is sprayed with a spiral pump, and the mud is sprayed onto the permanent lining. The spray coating is composed of sintered magnesia or magnesia-calcium sand, a binder, a plasticizer and organic fiber. The CaO/SiO2 of magnesia can be controlled above 2, and a small amount of raw dolomite or limestone fine powder can be added to increase the CaO content, which is not only beneficial to the purification of molten steel, but also conducive to the disintegration and shedding of the coating. The binder can be instant polyphosphate, instant water glass or composite polyphosphate, and the plasticizer includes soft clay, carboxymethyl cellulose, calcium lignin sulfonate, etc. The thickness of the spray coating is determined according to the use requirements, requiring 45mm~60mm for 20 to 30 heats, and 60mm~80mm for 30 to 40 heats.

With the advancement of iron and steel metallurgical technology, not only the service life of the tundish is required to be long, but also higher requirements are placed on the cleansing effect and thermal insulation effect of steel, so there is an ultra-lightweight (volume density 1.4g/cm3) magnesium spray coating. At present, the main methods for manufacturing ultra-light spray coatings are: using lightweight aggregates, adding fibers, adjusting particle size composition, and adding foaming agents.

Although the service life of tundish coatings and spray coatings is longer than that of silicon insulation boards, with an average service life of about 10 hours and a maximum of 24 hours, and it has a purifying effect on molten steel, there are disadvantages such as high labor intensity, long maintenance time, and complex baking process during spraying.

Alkaline dry material: Since 2000, with the promotion of tundish rapid nozzle replacement technology, higher requirements have been put forward for tundish working linings, and new alkaline dry materials have been applied and promoted. Dry materials are easy to construct, simple to bake, and labor intensity is greatly reduced. They can be constructed under any climatic conditions and have a long service life of more than 40 hours.

The alkaline dry material of the tundish is composed of sintered magnesia sand, magnesia calcium sand or fused magnesia sand, magnesia calcium sand and medium-high temperature sintering agent, and a small amount of low-temperature binder. The sintering agent includes magnesia calcium iron sand, soft clay, borate, iron scale, etc. The purpose of adding a small amount of low-temperature binder is to produce strength after the mold is baked at 200℃~300℃, so that the lining has shape retention. The binder is generally a powdered phenolic resin. A steel company in Shanxi studied the dry material of the tundish and found that: fused magnesia sand is used as the main raw material, the ratio of aggregate to matrix material is 65:35, among which the aggregate adopts three-level particle grading of 5mm~3mm, 3mm~1mm and <1mm; the matrix material includes two kinds of fine powders of <0.044mm and <0.088mm; the binder adopts powdered phenolic resin containing hardening accelerator, and the addition amount is preferably 6%; the sintering agent is metaphosphate, and the addition amount is preferably 2%; the modifier is a synthetic material containing Al2O3, and the addition amount is preferably 3%. The average service life of fused magnesia dry material is more than 40 hours, while the service life of sintered magnesia dry material can reach 24 hours.

Since it does not need to be blended with water, sintered magnesia calcium sand can be used to prepare dry materials with different CaO contents, which is beneficial to molten steel purification, improve the service life of the working lining, and can be cast in multiple furnaces. The remaining lining is easy to remove (fall off) after use. However, during the firing process, phenolic resin decomposes some cresol, formaldehyde, xylenol and other components, which cause great pollution to the environment, and the residual carbon after solidification pollutes the molten steel, which is not suitable for low-carbon steel. A refractory enterprise in Inner Mongolia explored the binder of magnesia dry material and found that the composite addition of metasilicate, phosphate and borate with an addition amount of about 6% is good; and the addition of α-Al2O3 and CaCO3 mixed micropowder generates spinel at high temperature accompanied by volume expansion, supplements volume shrinkage, and stabilizes the overall volume. The decomposition of CaCO3 produces some micropores to increase thermal insulation performance.

Composite material of slag retaining weir

Slag weir (wall): The continuous casting tundish is equipped with a slag weir (wall), which can change the flow state of molten steel in the tundish, increase the residence time of molten steel, promote the floating of inclusions in molten steel, and play a role in purifying molten steel. Slag weirs (walls) are of high aluminum and magnesium types. High aluminum slag weirs have good thermal shock resistance, strong resistance to slag erosion and molten steel scouring. Magnesium slag weirs can absorb AI2O3 and SiO2 inclusions in molten steel, improve the cleanliness of molten steel, and will not cause secondary oxidation of molten steel. my country’s magnesium slag weirs use magnesium castables made of electro-melted or sintered magnesia sand and silicon micropowder to form a MgO-SiO2-H2O system cohesion and combination, and add explosion-proof agents and dispersants, and some add 2% steel fiber.

Magnesium slag weirs have a long service life and are easy to penetrate, while aluminum-magnesium slag weirs have better erosion resistance, but are not as good as magnesium slag weirs for the purity of molten steel. A composite slag retaining weir is used, that is, the slag line uses aluminum-magnesium castables, and the molten steel area uses magnesium castables. After vibration molding, the two materials are combined into one to form a composite slag retaining weir. It is very important to make the two castables well compounded and have good construction performance. Therefore, it is necessary to select a good retarder for magnesium material, select SiO2 micropowder with a pH value close to 7 or slightly greater than 7, and the water reducer is a composite of tripolyphosphate and organic water reducer, so that the magnesium castable and the aluminum-magnesium castable have the same construction effect. The use temperature, slag amount, and slag liquid level fluctuation amplitude of the tundish of each steel plant are different. The production ratio of the two materials should be determined according to the actual situation. Generally, the upper one-third is aluminum-magnesium, and the remaining two-thirds are magnesium castables.

Filter: In order to better purify the molten steel, installing a ceramic filter that can remove non-metallic inclusions on the wall next to the tundish is one of the effective measures. The filter is divided into foam filter, mesh filter and annular filter, and its functions are different. The structural forms include slit type, straight hole type and dispersion type.

Bottom blowing air brick: air bricks are set near the slag weir of the tundish to blow argon, so that the inclusion content is reduced by more than 20% compared with no argon blowing. Compared with other methods that can only remove larger inclusions, the argon blowing technology of the tundish plays a particularly important role in removing tiny inclusions of about 50μm to ensure the quality of special thin steel (such as automobile plate steel). The airway structure and operation method of this air brick are different from other air bricks. There are also many ways to blow air, so that the gas carries the inclusions to float up without blowing away the protective slag, such as burying air pipes, installing air beams, and burying air permeable elements in the slag weir or at the bottom of the ladle.

Flow stabilizer: The flow stabilizer is a functional refractory material that stabilizes the flow state of molten steel injected into the impact zone of the tundish, improves the flow field of molten steel in the tundish, promotes the floating of inclusions, prevents slag from being involved in molten steel and causes internal quality defects of continuous casting billets.

Covering agent: The heat dissipation of the molten steel surface in the tundish is very large, accounting for more than 90% of the heat loss of the tundish. The tundish molten steel covering agent plays an important role in keeping the molten steel warm, reducing heat loss and temperature drop during steel pouring, absorbing floating inclusions in the molten steel, improving the quality of the molten steel, and preventing the secondary oxidation of the molten steel in the tundish, giving full play to the metallurgical function of the tundish. Therefore, the covering agent is required to have less erosion on the lining of the tundish and the ladle casing and good operability: that is, it should spread well on the surface of the molten steel, not form a crust during the steel pouring process, and be easy to clean after the steel pouring is completed and will not affect the unpacking operation. The covering agents used are mainly: single-layer covering agent (such as carbonized rice husk, composite slag), double-layer covering agent (carbonized rice husk + composite slag).