Monoblock stopper is one of the equipment for continuous steel casting. Monoblock stopper is mainly used for the main function of opening and closing the tundish. Monoblock stopper controls the position of the stopper head to the nozzle of the tundish to adjust the flow of molten steel into the mold. In addition to automatically controlling the flow of molten steel from the tundish to the mold, argon and other inert gases can also be blown into the tundish through the argon blowing hole of the stopper. Monoblock stopper has the functions of controlling steel flow and purifying molten steel. Monoblock stopper is only used when pouring starts and stops pouring, and is usually in an open state.

Monoblock Stopper Advantages:

- High thermal shock resistance suitable for both cold & hot tundish applications.

- Excellent corrosion resistance at slag zone & noise for longer sequence casting.

- Option of Argon injection, ceramic or steel thread for stable holding.

Monoblock Stopper Function:

The primary function of a monoblock stopper rod is to control the flow of molten steel from the ladle into the tundish during continuous casting. It acts as a movable plug that can be raised or lowered to open or close the flow passage, thereby regulating the steel flow rate. Monoblock stopper rods are installed and maintained by skilled operators. Proper installation, alignment, and periodic inspections are essential to ensure the effective functioning of the stopper system and prevent issues such as leakage or excessive wear. The continuous casting process in steel production relies on precise control of molten steel flow. Monoblock stopper rods play a critical role in this process, acting as the workhorse for regulating steel delivery from the ladle to the tundish.

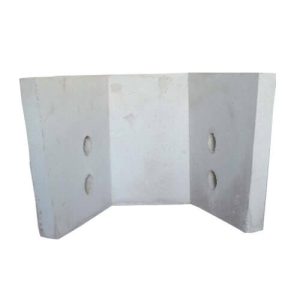

Monoblock Stopper nose is a crucial area which is subjected to maximum erosion & corrosion. Monoblock stopper rods are typically made from high-quality refractory materials, such as alumina, magnesia, or zirconia, depending on the specific application requirements. They are designed as a single-piece structure, hence the term “monoblock,” which ensures strength and integrity during operation.