AOD furnace mainly smelts stainless steel. 75% of the world’s stainless steel is smelted by AOD furnaces. At the beginning of the AOD furnace, oxygen is blown to oxidize and decarburize. During the oxidation period, the oxidizing property of the slag is enhanced and the temperature rises to above 1700; At this time, the alkalinity of the slag is still very low; finally, lime is added for desulfurization, and desulfurization requires high alkalinity slag. During the whole smelting process, the slag changes from acidic to basic atmosphere, from oxidative atmosphere to reducing atmosphere and then to intermittent operation. The lining temperature is high and fluctuates considerably.

By improving smelting conditions and taking gunning maintenance and other measures, the service life of AOD furnaces generally reaches more than 70 heats, and many of them exceed 100 heats. For AOD furnaces, magnesia chrome bricks are generally used. Due to the complex production process of magnesia-chrome bricks, ultra-high temperature firing, high energy consumption, high cost, especially environmental pollution problems, magnesia-chrome bricks are gradually replaced by magnesia-calcium bricks.

At present, the development trend of refractory bricks for AOD furnaces is that there are less and less magnesia-chrome bricks, more and more magnesia-calcium bricks, and some parts use low-carbon magnesia-calcium materials. There are also asphalt impregnation points for magnesium-calcium materials. It is worth pointing out that when the smelting temperature is high, carbonaceous refractories are not suitable due to internal redox reactions. Use magnesia-chrome bricks or magnesia-calcium bricks.

The main reasons for the damage of MgO-Cr2O3 refractory lining used in AOD furnace

(1) High smelting temperature and long acidic slag action time lead to melting and penetration of the furnace lining;

(2) Thermal spalling and structural spalling caused by temperature fluctuations;

(3) Rapid gas → slag → molten steel eddy erosion, especially the erosion caused by the violent stirring of slag and molten steel. Therefore, the refractory materials for A0D furnaces should have good thermal shock stability (TWB), high slag resistance, strong resistance to high temperature molten steel and slag erosion and mechanical damage, and at the same time, the refractory materials should have high refractoriness, low porosity, and sufficient strength.

In other words, magnesia-chrome bricks have high slag resistance to acidic slag, but poor resistance to high basicity slag. Mag-Chrome and Mag-Carbon types of refractory are generally used for the VOD. But for AOD sintered dolomite refractory is in used, because of their exhibiting nature in both oxidizing and reducing environment. But there is a problem in using this, which is that on reheating it got shrinkage and due to this in processing of stainless steel making, slag or metal can penetrate between two bricks, so to remove this phenomena there is suitable additives are added so that these bricks shows +ve PLC.

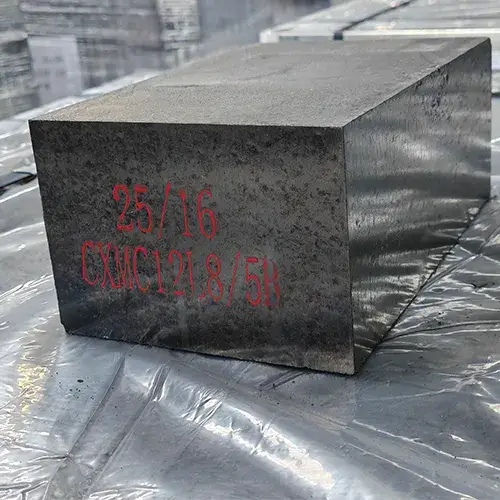

Magnesia carbon brick used for AOD

Magnesia carbon brick for AOD lining is resin-bonded and made with a high proportion of magnesite for very high erosion and slag resistance. It offers good oxidation resistance due to use of high purity flake graphite. It has good performance in thermal resistance, corrosion resistance and spalling resistance. It iswidely used in converters, EAFs, ladles and refining furnaces.