The effects of carbon content variation on the slag resistance, oxidation resistance, high-temperature flexural strength, and thermal shock stability of magnesia-carbon bricks were investigated. The results indicate that as carbon content increases, the bulk density and compressive strength of the magnesia-carbon bricks decrease. When carbon content ranges between 6% and 8%, the bricks exhibit superior high-temperature flexural strength, thermal shock stability, slag erosion resistance, and oxidation resistance. At lower carbon contents, slag erosion resistance diminishes. At 14% carbon content, oxidation resistance is the poorest.

With the development of the steel industry, the proportion of ultra-low-carbon steel production continues to increase. To address the issues of high thermal loss and carbon addition to molten steel associated with traditional magnesium-carbon bricks, low-carbon magnesium-carbon bricks are gradually becoming a research focus. However, as carbon content decreases, the material’s high-temperature properties also decline, with the most noticeable impacts being reduced thermal shock stability and slag resistance. It is well known that reducing carbon content in magnesia-carbon bricks lowers thermal conductivity and increases elastic modulus, thereby degrading thermal shock stability. Additionally, decreased carbon content enhances the wettability of molten slag and molten steel with the material, worsening slag resistance and molten steel permeability [3]. In recent years, Japan has seen significant advancements in low-carbon magnesia-carbon bricks utilizing nanotechnology. This study primarily investigates the impact of varying carbon content on magnesia-carbon brick properties, develops low-carbon magnesia-carbon bricks, provides reliable options for smelting different steel grades, reduces environmental pollution caused by magnesia-carbon bricks, and enables efficient resource utilization.

Experimental process

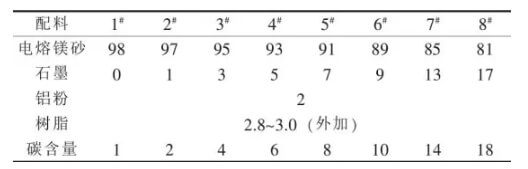

This experiment utilized 97% MgO fused magnesia, <196μm flake graphite, and aluminum powder as raw materials, employing liquid thermosetting phenolic resin as the binder. Materials were mixed according to the formulation in Table 1. The resin-coated aggregates were wet-mixed for 1–2 minutes, followed by the addition of fine powders and kneading for approximately 40 minutes. The mixed material was sealed in bags for 12 hours. Molding was performed at 0.2 MPa pressure per unit area to produce cylindrical specimens (50 mm × 50 mm) and bar specimens (25 mm × 40 mm × 130 mm). The molded specimens were dried at 200°C for 24 hours.

Analysis of Experimental Results

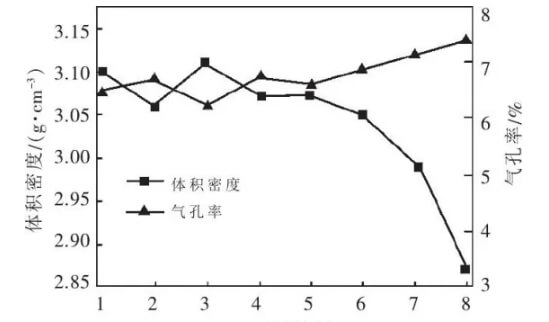

Figure 1 shows the effect of carbon content variation on the bulk density and porosity of the specimens. As shown in Figure 1: The bulk density of the specimens generally decreased with increasing carbon content, reaching a maximum value of 3.13 g·cm⁻³ at 4% carbon content. Between 6% and 10% carbon content, the bulk density showed no significant change with increasing carbon content. When carbon content exceeded 10%, the bulk density decreased markedly. With increasing carbon content, the apparent porosity of the specimens exhibited an increasing trend. It reached a minimum at 4% carbon content. When carbon content exceeded 10%, the apparent porosity of the specimens increased significantly.

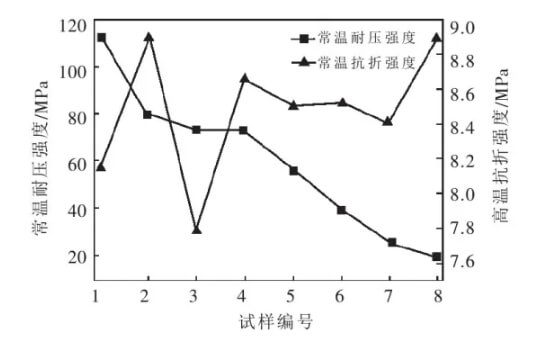

Figure 2 shows the effect of carbon content variation on the room temperature compressive strength and high temperature flexural strength of the samples. The experimental samples were cut into specimens with dimensions of 130mm × 25mm × 25mm, and the high temperature flexural strength was tested according to the national standard GB/T22589-2008.

As shown in Figure 2, the room temperature compressive strength of the samples decreases with increasing carbon content; the carbon-free samples have the highest compressive strength, reaching 112.1 MPa; when the carbon content is between 2% and 6%, the compressive strength of the samples does not change significantly with increasing carbon content; when the carbon content is >6%, the compressive strength of the samples decreases significantly. The high temperature flexural strength of magnesia-carbon bricks is a very important property. A high high temperature flexural strength means greater resistance to shear stress caused by temperature gradients, making the product less prone to spalling during use. Products with high high temperature flexural strength also have improved resistance to material impact and abrasion, and enhanced slag resistance. As shown in Figure 2, the high-temperature flexural strength of the magnesia-carbon brick samples exhibits a broken-line change with increasing carbon content. The magnesia-carbon brick sample with 2% carbon content has the highest high-temperature flexural strength at 8.90 MPa, while the sample with 4% carbon content has the lowest at 7.77 MPa. When the carbon content is between 6% and 18%, the high-temperature flexural strength of the magnesia-carbon brick samples shows a trend of first decreasing and then increasing with increasing carbon content.

During use, the thermal shock stability of magnesia-carbon bricks changes due to rapid changes in ambient temperature. The flexural strength loss rate was determined according to formula (1) after three water cooling cycles at 1100℃. The magnitude of the flexural strength loss rate was used as an indicator of the thermal shock stability of the sample.

With increasing carbon content, the loss of flexural strength after thermal shock first decreases and then increases. Specimen #1 exhibits the highest flexural strength loss rate, while specimen #5 shows the lowest. When carbon content exceeds 14%, severe surface spalling occurs due to carbon oxidation, resulting in noticeable slag shedding and flaking. In contrast, specimens with 2%, 4%, and 6% carbon content exhibited no significant spalling after thermal shock. Due to the low carbon content, the magnesium-carbon brick specimens expanded or contracted with temperature changes, generating internal stresses within the material. This resulted in thermal stress damage, leading to an increased loss rate of flexural strength after thermal shock.

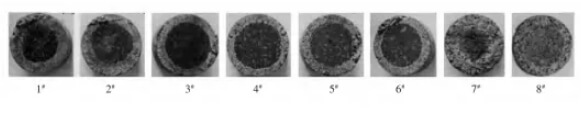

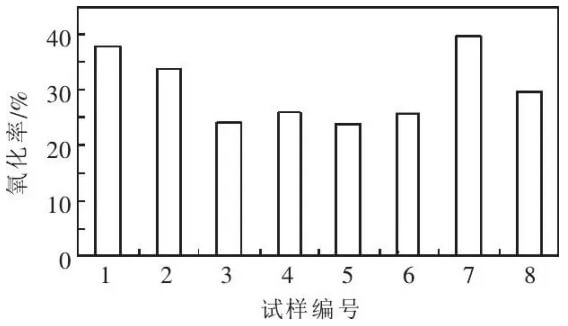

During service, erosion of magnesium-carbon bricks primarily results from graphite oxidation, forming pores at the original graphite locations. Molten steel and slag penetrate these pores, corroding the brick body. Figure 4 shows oxidation resistance photographs of magnesium-carbon bricks after 3 hours of holding at 1600°C.

As shown in Figures 5, sample #7 exhibited the most severe oxidation, followed by samples #1, #2, and #8. The surfaces of samples #7 and #8, due to carbon oxidation, were porous and porous, allowing slag to easily penetrate and exacerbating erosion. When the carbon content was between 4% and 10%, the oxide layer thickness and oxidation rate were similar in the oxidation photographs. The decarburized layer of the samples was relatively dense, improving the material’s oxidation resistance. Changes in carbon content had little effect on the oxidation of magnesia-carbon bricks. It can be concluded that both excessive and insufficient carbon content are detrimental to the oxidation resistance of magnesia-carbon bricks.

Simultaneously, during use, slag erosion causes the magnesia-carbon bricks to peel off structurally and accelerates the dissolution and corrosion process. When magnesia-carbon bricks come into contact with slag during use, the slag’s penetration into the brick’s interior and the dissolution of brick components into the slag become significant causes of damage. Slag resistance tests were conducted by placing slag inside magnesia-carbon bricks; the slag composition is listed in Table 2.

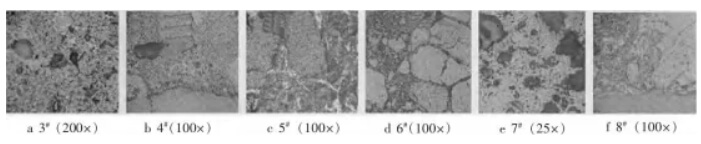

As shown in Figure 6, slag infiltrates into the interior of the product along the magnesite grain boundaries. A small amount of graphite is present on the surface of the erosion layer, which exhibits a loose surface structure and high porosity. As shown in Figure 6b, Sample 4 exhibits minimal slag adhesion with no discernible decarburization layer. The eroded layer shows slight slag erosion of both aggregate and matrix, accompanied by particle detachment on the surface. Within the matrix, magnesite grains have grown larger, with silicate phases filling the intergranular spaces. This structure impedes further slag penetration, demonstrating strong resistance to slag erosion. Figure 6c shows that Sample 5 exhibits substantial residual graphite with uneven distribution, with slag solution eroding the matrix. Figure 6d indicates that in Sample 6, the slag solution simultaneously erodes both the matrix and aggregate. The reaction causes fragmentation of the orthomagnesite particles, forming numerous pores at the reaction interface. The slag solution penetrates the interior of the specimen along these pores, resulting in low slag erosion resistance. Figure 6e shows that sample 7 developed a decarburized layer on its surface, with enlarged magnesite crystals and high porosity. Figure 6f indicates that sample 8 did not form a decarburized layer, with a small amount of graphite present in the reaction zone. While high-carbon magnesia-carbon bricks enhance resistance to slag erosion, the high carbon content in these samples led to graphite oxidation, forming a decarburized layer on the surface and causing specimen failure.

Conclusion

(1) As carbon content increases, the bulk density and compressive strength of magnesia-carbon bricks decrease.

(2) At carbon contents between 6% and 8%, magnesium carbon bricks exhibit optimal high-temperature flexural strength, thermal shock stability, slag resistance, and oxidation resistance. Lower carbon content reduces slag erosion resistance. Magnesium carbon bricks with 14% carbon content demonstrate the poorest oxidation resistance.

(3) For smelting low-carbon steel, magnesium carbon bricks with carbon content between 6% and 8% should be selected.