1.The application and features of the overall stopper rod

At present, the common aluminum-carbon integral stopper rods have rod heads made of high-aluminum-carbon, aluminum-zirconium carbon, magnesium-carbon or other materials. Units 5 to 10 used aluminum-carbon-zirconium integral plug rods before 2011, which were used in conjunction with the nozzles. The liquid level control of the mold is a vortex automatic control device. The flow rate of molten steel entering the mold is adjusted by controlling the position from the head of the stopper rod to the water inlet of the tunbag. Argon can be blown into the tunbag through the argon gas hole to prevent the water inlet from being blocked. It features excellent erosion resistance, strong anti-erosion ability, oxidation resistance and high strength, and is suitable for long-term continuous casting in multiple furnaces. During the production of SPHC steel grade, the material of the stopper rod was prone to slag formation and flow-forming at the rod head. Later, the material of the stopper rod head was changed to spinel. After the change to spinel, there were multiple accidents of stopper rod breakage.

2.Overview of the plug rod breakage accident

2.1 Statistics of plug rod breakage accidents

Through statistical analysis of the quality status of the tundish stopper rods from four manufacturers, namely A, B, C, and D, it was found that only once was CCSB ship plate steel produced when the stopper rods broke, while the rest were all Q235B steel. Moreover, no stopper rod breakage incident occurred in Manufacturer D, and there were significant differences in the service life and fracture location of the tundish when the stopper rods from other manufacturers broke.

2.2 Morphological Characteristics of Plug Rod Fracture Sites

C manufacturer’s plug rods exhibited the highest number of fractures, predominantly occurring at the rod head. Measurement and inspection of C manufacturer’s failed plug rods revealed that fractures at the rod head typically occurred 5 to 10 cm from the tip. Longitudinal sectioning of undamaged plug rods from the same batch using specialized equipment also revealed distinct cracks.

3.Analysis of the causes of stopper rod fracture

Based on the process conditions of units 5 to 10 in the Second Steelmaking Plant, process technicians summarized the causes of stopper rod breakage, mainly in the following four aspects.

3.1 Steel Composition

The material of the stopper rod must be determined based on the steel grade produced by the steel mill, the steel treatment method, and the continuous casting time in the tundish. For steel grades treated with Ca and Si, the head of Al-C or SiO2-C stopper rods erodes faster, often leading to uncontrollable steel flow. When the amount of Ca added exceeds a certain level, the damage to Al-C stopper rods tends to increase. The main reason is that when Ca is added to a certain amount, CaO in the steel reacts with Al2O3 to form low-melting-point substances, thereby increasing the erosion of Al-C refractory materials by Ca in the steel.

3.2 Installation of the stopper rod and the water inlet

During installation and adjustment, stopper rods are generally required to have a certain biting edge. However, during the casting process, stopper rods are prone to misalignment, which can easily lead to molten steel flow deviation. Severe deviation can cause sticking and leakage accidents.

3.3 Baking status of intermediate bread

Based on the material characteristics of the intermediate ladle lining, stopper rod, and inlet, the baking curves used for machines 5-10 were: low heat for 30 minutes, medium heat for 30 minutes, and high heat for 1-2 hours. However, due to changes in the production plan, the actual baking process could not be completely carried out according to this baking curve. In addition, the baking gas used in machines 5-10 was converter gas, which has a high moisture content, and the gas drainage facilities were rudimentary, resulting in unsatisfactory drainage.

3.4 Design and manufacturing process of the stopper rod

All stopper rods are formed using isostatic pressing, and their shape and size depend on the capacity of the tundish. The upward distance of the stopper rod determines the liquid level height in the crystallizer, which can generally be observed on the scale on the side of the opening and closing mechanism. The upward distance of the stopper rod determines the gap between the stopper rod head and the nozzle bowl, thus controlling the flow rate of molten steel entering the submerged entry nozzle, which is related to the radius of their own arc curves. When the stopper rod or nozzle is eroded, the stopper rod will move downward, resulting in a decrease in the stopper rod opening. Severe or uneven erosion of the stopper rod head will seriously affect the flow control effect of the stopper rod. An investigation revealed that the rod head size provided by Manufacturer C was unsuitable, frequently resulting in rod head breakage and poor flow control.

The basic production process of the stopper rod is as follows: raw material preparation and batching → mixing and granulation → clamping and drying → isostatic pressing at 120 MPa → lathe turning → shuttle kiln firing → roller conveyor fully automatic coating spraying → X-ray non-destructive testing. Manufacturer C’s improper control over the ingredient formulation resulted in poor bonding between the stopper head and the body, leading to significant internal stress after baking.

4.Control measures to prevent stopper rod breakage

4.1 Adjust the steel composition and improve the deoxidation and alloying process

When stopper rods broke at machines 5-10, the steel produced was mostly Q235B steel, indicating a correlation between the steel composition and the stopper rod breakage. Therefore, the deoxidation and alloying methods for molten steel were studied, and the process was improved. The deoxidation and alloying materials used in the second steelmaking plant mainly included Si-Mn-Fe, CaBaAlSi (composite deoxidizer), and CaSi wire. The alloy addition sequence was: CaBaAlSi (composite deoxidizer) → Si-Mn-Fe (CaBaAlSi addition amount 1.5-2.0 kg/t, Si-Mn-Fe addition amount adjusted according to the final residual Mn). The alloy was added between the start of tapping and 2/3 of the way through, ensuring the composition at the argon station was within the target range. After the molten steel entered the refining furnace, the C, Si, and Mn content was fine-tuned according to the initial refining composition. Before exiting the refining station, 1.5-2.0 m/t of silicon-calcium wire was fed at a feeding speed of 1. 5 ~ 2 m/min. After wire feeding, the soft blowing time is ≥8 min, and yellow-white slag is produced during steel tapping. The improved mechanism of reaction between molten steel and stopper head material is weakened, thus improving the corrosion resistance of the stopper head.

4.2 Improved stopper rod installation method

Revise the installation and adjustment method for the stopper rod. Before adjustment, check the crossbeam of the opener and closer, and check whether the stopper rod is straight and whether the rod thread is intact. Insert the connector into the screw rod and tighten the rod screw until the connector is flush with the rod. The upper rod bite should be 3 to 5 mm, without reverse bite or off-center bite, and the allowance of the opener and closer should not be less than 30 mm.

4.3 Improve the baking effect of intermediate bread

The intermediate bread is baked strictly according to the baking curve, ensuring that it is baked rapidly to above 1000℃ within 1 to 2 hours. The temperature of the stopper rod and the top water inlet is measured with an infrared thermometer to improve the baking effect.

4.4 Redesign the dimensions of the stopper head

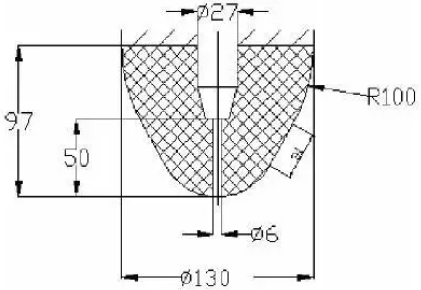

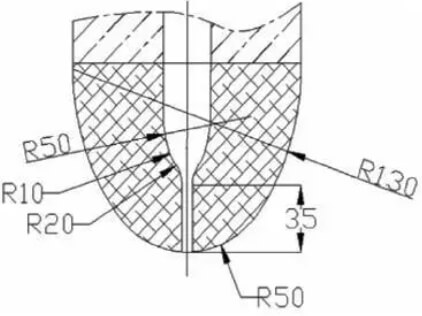

In the design process of the integral stopper rod and submerged nozzle, the shape of the integral stopper rod head and the submerged nozzle bowl are often involved. The design first requires determining the flow diameter of the submerged nozzle, thereby determining the shape and opening of the nozzle bowl; based on this, the shape and length of the integral stopper rod head that matches it are then determined. Based on the production conditions of the casting machine and drawing on the experience of other manufacturers, the process technicians, together with Manufacturer C, redesigned the stopper rod head. The shapes of the stopper rod head before and after the improvement are shown in Figures 1 and 2. At the same time, the overall length of the stopper rods for machines 7-9 was adjusted from 1590 mm to 1560 mm to reduce rod vibration. After improving the stopper rod head design, the process technicians communicated with the manufacturer of the automatic crystallizer liquid level control system and adjusted the control program to ensure the stability of the crystallizer liquid level.

4.5 Optimize and adjust the material of the stopper rod head

Experiments have shown that MgO-C and ZrO2-C materials have higher erosion resistance than Al2O3-C materials; spinel-C materials are better than MgO-C and ZrO2-C materials; and spinel-C materials produced by electrofusion have higher erosion resistance than those produced by sintering. Because the body and head of the stopper rod are made of different clay materials, their bulk density, porosity, and strength differ significantly, especially their coefficients of thermal expansion. If they are directly bonded, they are prone to tipping over during use. Therefore, an intermediate layer is designed to ensure good bonding between the two materials [4]. Based on the production conditions of units 5-10, the material of the stopper rods was optimized and improved. The rod body remained aluminum-carbon, but the stopper rod head was changed from ZrO2-C to fused alumina-magnesium spinel. The spinel formulation was adjusted, and the amount of graphite added was increased, improving the thermal shock stability of the rod head (tested at 1200℃ with rapid cooling in circulating water). The number of thermal shock tests increased from 3-4 to 6. Through the implementation of these measures, stopper rod breakage accidents were controlled, and the proportion of stopper rod breakage accidents in unplanned downtime accidents decreased year by year, from 15.66% in 2011 to 13.30% in 2012, achieving good results. In 2013, due to a change in the refractory material supplier, the proportion of stopper rod breakage accidents rose again, reaching 25%. After investigation, it was found that the stopper rod head material used by the new refractory material supplier was unsuitable, and the size of the tundish top nozzle differed from the original design, resulting in breakage accidents still occurring even after using stopper rods from other manufacturers. After the relevant issues were resolved, stopper rod fractures decreased significantly, with only one stopper rod fracture incident occurring between December 2013 and April 2013.