1.Causes of leakage accidents at the ladle outlet of converter:

Leakage incidents at the ladle outlet of a converter are often closely related to multiple factors. Experienced technicians indicate that the following aspects are the primary causes of such accidents:

(1) Insufficient sintering of the refractory lining in the tapping nozzle caused refractory material spalling during tapping.

(2) Equipment aging: As the core equipment in steel production, converters experience wear and aging of internal structures and materials after prolonged use. Particularly at the tapping nozzle, which endures extreme conditions of high temperature, pressure, and corrosion, cracks and deformation are prone to occur, leading to steel leakage incidents.

(3) Improper operation: Converter operation involves multiple procedures and parameters. If operators lack sufficient skill or deviate from standard protocols, it can cause excessive fluctuations in molten steel within the furnace. This creates impact forces on the tapping nozzle, increasing the risk of leakage.

(4) Inadequate Maintenance: After prolonged use, the tapping nozzle sleeve may become severely corroded without timely replacement. Routine maintenance and inspections are critical for ensuring the converter’s safe and stable operation. Neglecting thorough maintenance allows potential hazards to accumulate, ultimately triggering steel leakage incidents.

2.Steel leakage during blowing

(1) Causes of steel leakage during blowing:

1) The furnace has been in operation for an extended period, resulting in severe damage to the furnace lining and thinning of the furnace bottom.

2) Prolonged use of low taphole positions and high oxygen pressure during refining.

3) Failure to perform furnace repairs over an extended period has led to significant damage to the lining.

(2) Treatment measures for steel leakage accidents during blowing:

1) Ladle truck operators shall monitor the converter throughout the blowing process and immediately move the ladle truck away from beneath the converter upon detecting a steel leak.

2) Upon detecting a steel leak in the converter, ladle truck operators shall immediately notify the control room and report to the furnace chief.

3) Upon learning of a steel leak, the furnace chief shall immediately instruct the ladle operator to cease blowing.

4) Upon learning of a steel leak, the furnace chief shall assume unified command and document the incident for compilation.

3.Steel leakage during tapping:

(1) Causes of steel leakage during steel tapping:

1) During the later stages of the furnace’s service life, the inner lining bricks suffered severe damage and spalling.

2) Due to the long-term absence of a repair plan for the furnace lining on the tapping hole side, the lining on that side experienced significant erosion.

(2) Treatment measures for steel leakage accidents at the tapping hole

1) Slag ladle operators and ladle carriers shall monitor the entire converter process during tapping. Upon detecting a leak, immediately move the slag ladle from beneath the furnace to the slag bay and position the ladle carrier at the ladle berthing area.

2) When operators of the ladle car and steel ladle car under the furnace detect a leak, they shall immediately notify the dispatch room and furnace operator.

3) During the entire tapping process, the tapping operator shall monitor the converter. If a leak is detected, they shall immediately raise the furnace, halt tapping, and report to the furnace operator.

4) Upon receiving notification of a leak, the furnace chief must immediately order the furnace lifted and tapping halted.

5) After learning of the leak, the furnace chief shall coordinate unified command and compile an incident record.

6) Notify the preparation workshop to immediately relocate the ladle.

7) Cool the leaked molten steel with water, then organize handling of the solidified steel.

8) If molten steel remains in the furnace, proceed according to the frozen furnace handling protocol.

4.Protection and accident prevention:

Regular inspections should be conducted to monitor the wear and tear of various materials at the tapping hole. Replace any eroded or damaged tapping hole liners promptly. When installing new tapping hole liners, ensure the refractory materials are fully sintered.

Steel leakage incidents at converter tapping nozzles are common safety issues in steel production, arising from complex and diverse causes. By strengthening equipment inspections and upgrades, improving operational proficiency, and enhancing maintenance practices, we can effectively reduce the likelihood of such incidents and ensure the safe and stable operation of converters.

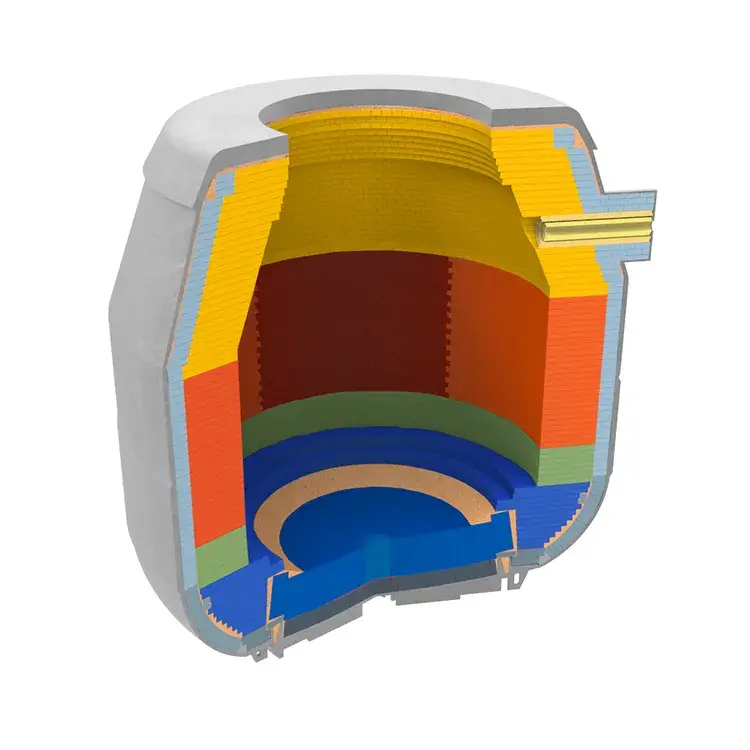

BOF Furnace