Magnesia carbon bricks are a new type of refractory material that emerged in the 1970s. Made from high-temperature sintered or fused magnesia and carbon, and using various carbon binders, these unfired refractory materials retain the advantages of carbon-based refractories while overcoming the inherent shortcomings of alkaline refractories, such as poor spalling resistance and slag absorption.

To this day, magnesia carbon bricks are still widely used in the steel and metallurgical industry. Their application has improved various technical and economic indicators of converters and reduced refractory consumption. Furthermore, as an unfired product, magnesia carbon bricks save at least 80% in fuel production compared to traditional fired magnesia dolomite bricks.

Because their components, magnesium oxide and carbon, both of which have high melting points and are immiscible, magnesia carbon bricks possess high melting resistance.

Magnesia carbon bricks are composite structures composed primarily of magnesium oxide clinker, which exhibits strong resistance to alkaline slag, and carbon, which has poor wettability with molten slag. This gives them excellent slag resistance. In particular, they offer strong resistance to molten slag penetration, resulting in a much shallower penetration layer than older fired alkaline bricks.

Dry graphite possesses excellent thermal shock resistance, so these bricks inherit the excellent properties of graphite, offering high thermal conductivity, a relatively low linear expansion coefficient and elastic modulus, and high high-temperature strength. This virtually eliminates structural damage and spalling caused by cracking during use.

In addition to these excellent properties, magnesia carbon bricks also exhibit excellent thermal creep resistance, demonstrating exceptionally good creep resistance compared to other ceramic bonded bricks.

Since the advent of the oxygen converter, furnace lining materials have evolved through three stages: tar dolomite bricks, fired alkaline oil-impregnated bricks, and magnesia carbon bricks. Since the 1980s, steelmaking converters and their lining refractory materials have made significant progress. Steelmaking converters have progressed towards larger scale and greater automation, and are currently moving towards combined blowing and higher temperatures.

During the smelting process, the operating conditions and wear profiles of various converter components vary, necessitating the use of different refractory materials for each component.

(1) Furnace mouth: Due to the drastic temperature changes at the furnace mouth, the scouring of slag and high-temperature exhaust gas is more harmful, and the furnace door is hit when removing scrap steel and adding materials. Therefore, the refractory material used for the furnace mouth must have high thermal shock resistance and slag resistance, be resistant to the scouring of slag and high-temperature exhaust gas, not easy to hang steel and easy to clean.

(2) Furnace cap: The furnace cap is the part that is most seriously affected by slag erosion. It is also affected by temperature changes, carbon oxidation and scouring of dust-containing exhaust gas. Therefore, magnesia carbon bricks with strong slag resistance and thermal shock resistance are required.

(3) Charging side: The splashing of slag and molten steel during blowing can easily cause chemical erosion, wear and scouring on the charging side. The charging side is also directly hit and eroded by the charged scrap steel and molten iron, causing serious mechanical damage. Therefore, magnesia carbon bricks are required to have not only high slag resistance and relatively high high-temperature strength, but also relatively good thermal shock resistance. High-strength magnesia carbon bricks with added antioxidants are usually used.

(4) Steel tapping side: The steel tapping side is basically not subject to mechanical damage during charging, and the thermal shock effect is also small. However, it is subject to thermal shock and scouring of molten steel during steel tapping, and the damage rate is much slower than that of the charging side. When the same material as the charging side is used, in order to maintain the balanced life of the converter lining, a thinner structure than the charging side is used for masonry.

(5) Slag line area: The slag line is the area where the lining is in long-term contact with the slag and is severely corroded by slag. On the steel tapping side, the slag line is not obvious because the position of the slag changes with the steel tapping time. On the slag discharge side, due to the strong slag corrosion and the combined influence of other effects on the belly of the furnace during the blowing process, it is severely damaged. Therefore, it is necessary to build magnesia carbon bricks with excellent slag resistance.

(6) Both sides of the ear shaft: In addition to the damage caused by blowing, the two sides of the ear shaft are not covered with a protective layer on the surface and are not easy to repair. Therefore, the carbon in the lining material is easily oxidized, resulting in serious damage. High-grade magnesia carbon bricks with excellent slag resistance and strong oxidation resistance should be built.

(7) Hearth and bottom: These parts are subjected to intense erosion by molten steel during blowing, but the damage is generally less severe than other parts. Magnesia carbon bricks with low carbon content or tar dolomite bricks can be used. When high-speed blowing is used and the molten pool is shallow, the center of the bottom may be severely damaged. In addition, when bottom blowing is used, the damage to these parts may be aggravated, and the same material as the charging side of the furnace should be used. At present, in order to improve the technical and economic indicators of the converter, comprehensive masonry is generally used.

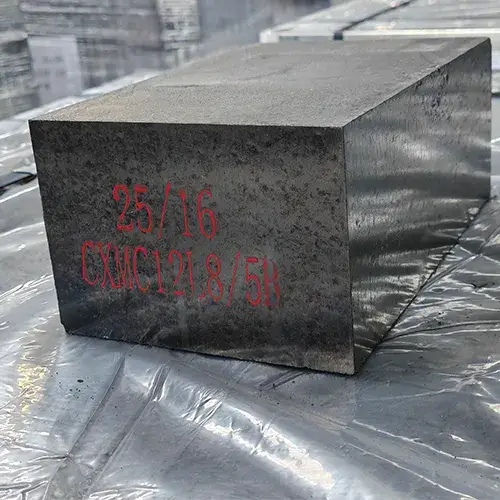

Magnesia Carbon Bricks