The aggregate for magnesia-carbon bricks used in ladle slag lines is generally ordinary fused magnesia with a MgO mass fraction of ≥97.5% or ≥98% (97.5% MgO mass fraction) or 98% (98% MgO mass fraction). However, in refining processes where the conditions are more demanding, large-crystal fused magnesia is often used. The carbon mass fraction is generally 10%-12%, and the antioxidants are typically aluminum powder, B4C, etc. Compared to magnesia-carbon bricks used in converters, the magnesia grade and crystal size of magnesia-carbon bricks used in refining ladle slag lines are relatively better.

Among the refining methods currently in use, LF refining has the shortest service life, the most demanding conditions, and the most severe damage. Generally speaking, the service life of magnesia-carbon bricks in the LF refining ladle slag line is 1535 cycles, but the specific situation varies depending on the specific operation.

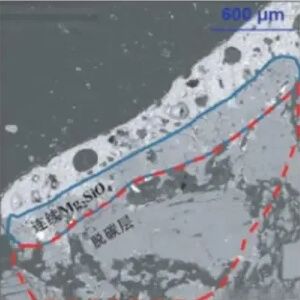

Figure 1 shows the microstructure of magnesia-carbon bricks used in LF slag lines. It can be seen that LF slag line bricks are also divided into a reaction layer, a decarburization layer, and a raw brick layer. However, compared to converter magnesia-carbon bricks, LF slag line magnesia-carbon bricks have the following characteristics:

① The amount of slag adhering to the surface of LF slag line magnesia-carbon bricks is very small, basically exposed, or only a thin layer;

② The working surface strength is very low, and the magnesia particles are almost unbonded;

③ The penetration depth of LF slag into the brick is very deep. The above-mentioned usage of magnesia-carbon bricks is related to the LF refining slag and operating process. The main components (typical values, mass fraction) of LF refining slag are CaO 58.24%, Al2O3 33.42%, SiO2 15.28%, FeO 1.75%, etc. LF slag with this composition is powdery at room temperature and cannot form a closed protective layer on the working surface of the magnesia-carbon bricks. The magnesia-carbon bricks are in an unprotected state, therefore, oxidation and decarburization of the magnesia-carbon bricks are relatively severe. LF slag has a relatively low viscosity at high temperatures, strong penetration ability in the decarburization layer, and high solubility for magnesium oxide. At the same time, the slag easily penetrates into the grain boundaries of periclase to dissociate magnesia particles, as shown in Figure 2 (SA in the figure is slag; TA is the intersection of three pieces). Therefore, the service life of Mg-carbon bricks in LF slag lines is relatively short.

The performance of magnesia is crucial for enhancing resistance to slag erosion. Shen et al. systematically studied the damage mechanism of magnesia-carbon bricks in the LF refining ladle slag line. The results showed that slag easily erodes aggregates with small MgO grain sizes, penetrating along periclase grain boundaries into the MgO aggregate and causing cleavage. Therefore, magnesia-carbon bricks for slag lines generally use fused magnesia with a purity of over 97%; the periclase crystals in this magnesia are generally relatively large. Furthermore, a CaO/SiO2 molar ratio of greater than 2 is generally required, so that the phases at the periclase grain boundaries are 2CaO·SiO2, 3CaO·SiO2, etc., which can minimize the formation of low-melting-point components such as CaMg(SiO4) and (Mn,Ca)(SiO3), and effectively inhibit slag erosion along the periclase grain boundaries. Wang Aiming et al. selected low-silicon, high-calcium fused magnesia (MgO mass fraction 97.70%) to study its effect on the performance of magnesia-carbon bricks in ladle slag lines. Its high-temperature strength was significantly better than that of the original magnesia-carbon bricks, which is crucial for enhancing its resistance to mechanical erosion by molten slag. Currently, in LF refining under harsh operating conditions, especially in ladle slag lines undergoing subsequent VD treatment, large-crystal fused magnesia is generally used. Furthermore, large-crystal fused magnesia is also commonly used in ladle slag lines with demanding LF operations; the periclase crystals in this magnesia are very large, generally larger than the magnesia particles in magnesia-carbon bricks. Therefore, the magnesia particles in magnesia-carbon bricks essentially lack periclase grain boundaries, thus reducing slag erosion along the periclase grain boundaries, but at a significantly higher cost.

The resistance of magnesia-carbon bricks to slag erosion is related not only to the properties of magnesia sand but also closely to the brick’s microstructure; a dense structure with good stress matching exhibits relatively better erosion resistance. This is related not only to the closest packing of particles but, most importantly, to the characteristics, content, and distribution of graphite.

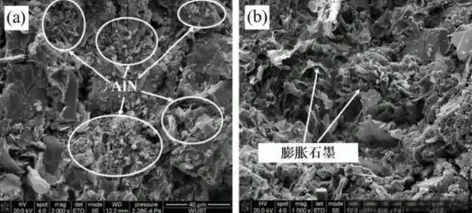

Because periclase has a relatively large coefficient of thermal expansion (linear expansion coefficient α = 14 × 10⁻⁶ ~ 15 × 10⁻⁶ K⁻¹ at 0–1500℃), magnesia sand particles will generate significant expansion stress and volume effects during thermal cycling. Therefore, controlling the graphite particle size and distribution to create a microstructure that inhibits slag penetration is crucial for improving the performance of magnesia-carbon bricks. Ouyang Junhua et al., in their study on the effect of graphite particle size on the properties of low-carbon magnesia-carbon bricks, found that replacing coarse graphite with fine graphite significantly improved the physical properties, oxidation resistance, and thermal shock stability of the magnesia-carbon bricks. This is mainly because smaller graphite particles leave smaller pores after oxidation, slowing down the oxidation rate. In addition, fine graphite has a larger specific surface area, making it easier to form a network structure that improves material properties. Zhu et al. utilized the properties of expanded graphite and introduced it into magnesia-carbon bricks, generating more network Al4C3 and layered AlN structures in the matrix, thereby improving the strength and toughness of the material, as shown in Figure 3.

To enhance the performance of magnesia-carbon bricks used in ladle slag lines, significant research has been conducted on carbon nanofiberization and graphite modification, making this a dynamic research direction. Zhu et al. compared the effects of three different forms of nano-carbon sources (nano-carbon black, carbon nanotubes, and graphene oxide) on the microstructure, mechanical properties, and thermal shock resistance of magnesia-carbon bricks. They also compared these results with those of conventional magnesia-carbon bricks containing 10% by mass of flake graphite prepared under the same conditions. The addition of nano-carbon had a positive impact on the in-situ formation of different quantities and forms of ceramic phases at 1000 and 1400℃, thus affecting its mechanical properties and thermal shock resistance. Magnesia-carbon bricks with added carbon nanotubes and carbon black exhibited higher residual strength retention, resulting in the same thermal shock resistance as conventional magnesia-carbon bricks even at a 5% by mass addition.

Carbon content is beneficial to the slag resistance of magnesia-carbon bricks, but when smelting materials such as pipeline steel X60~80 used in the petroleum industry and cord steel used in automobile tires, the carbon content of magnesia-carbon bricks should be as low as possible. This is called the decarbonization of magnesia-carbon bricks.