A novel anti-oxidation coating was applied to magnesia-carbon brick samples for laboratory testing and then applied to magnesia-carbon bricks in the slag line of a steel ladle for on-site testing. The results showed that below 1100℃, the coating provided excellent anti-oxidation protection for the magnesia-carbon brick samples, with the loose layer and decarburized layer thicknesses almost zero. The residual thickness of the coated magnesia-carbon bricks in the slag line was approximately 20mm greater than that of uncoated bricks under the same conditions. Applying the anti-oxidation coating to the magnesia-carbon bricks in the slag line could extend their service life by approximately 15%.

Currently, the working linings used in steel ladles, especially in the slag line area, mostly use carbonaceous refractory materials. Newly constructed steel ladles, before being used to hold molten steel, must be preheated to approximately 1000℃ in sequence from low to medium to high heat, a process that typically takes 20-30 hours, sometimes even longer. However, many steel ladle sites currently do not implement anti-oxidation measures for the carbonaceous working linings during the preheating process, resulting in a 20mm thick layer of oxidation and decarburization already formed on the working magnesia-carbon bricks when the lining is ready for use after preheating. A small number of steel ladle working layer magnesia-carbon bricks are coated with anti-oxidation paint after construction. However, because the paint needs to be mixed with water on-site, it is inconvenient to use, and other factors significantly reduce its anti-oxidation effect. This is the main reason why most steel ladle sites have long abandoned the use of anti-oxidation paint. The anti-oxidation paint for magnesia-carbon bricks in this experiment is a pre-prepared slurry with good adhesion, easy application, and a long shelf life.

Laboratory test results

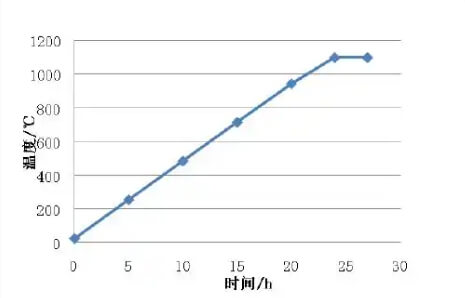

The chemical composition (w) of the MgO-C bricks used in the experiment was as follows: MgO 80.97%, C 14.65%, Al₂O₃ 2.68%, SiO₂ 1.04%, Fe₂O₃ 0.64%. The selected MgO-C bricks were cut into cuboids of 60mm × 50mm × 70mm. The coating was evenly applied to all surfaces of the sample (including three original brick surfaces and one cut surface) using a brush, leaving only the bottom surface and the center of one side surface uncoated as a control surface. The coating thickness was approximately 0.5mm. After being left to stand naturally for 5 hours, the sample was placed in an electric furnace and heated uniformly from room temperature to 1100℃ over 24 hours, and held at 1100℃ for 3 hours (the heating curve is shown in Figure 1). After natural cooling, the sample was removed.

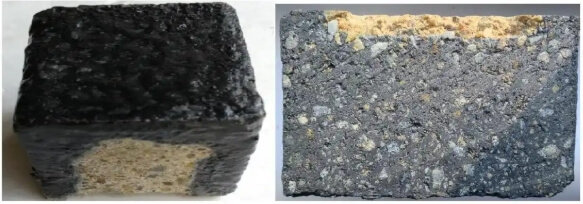

The appearance and cross-sectional appearance of the sample after firing are shown in Figure 2. As can be seen from Figure 2, after firing, the uncoated parts of the sample changed color and had a clear decarburized layer, with the loose layer and the decarburized layer being basically the same; while the parts coated with paint had almost no loose layer and decarburized layer.

Analysis of the above phenomena suggests that the binder of magnesia-carbon bricks is a phenolic resin-based carbonaceous material. When the temperature exceeds 450℃, the phenolic resin, acting as a binder, undergoes significant oxidation, leading to a marked decrease in the strength of the magnesia-carbon bricks. Graphite in the magnesia-carbon brick material also oxidizes significantly above 800℃, resulting in a substantial increase in porosity and a loose structure. The higher the carbon content of the magnesia-carbon brick, the more pronounced the increase in porosity and the looser the structure after oxidation. In Figure 2, the decarburized layer and loose layer in the uncoated areas are essentially the same because after a sufficiently long period above 800℃, the carbon in the resin binder and the graphite eventually reach the same oxidation depth. The coated areas and the interior of the sample block are uniformly black, without any loosening or decarburization, indicating that the coating provides good anti-oxidation protection for the resin carbon and graphite in the magnesia-carbon bricks at temperatures up to 1100℃.

Field Application and Discussion

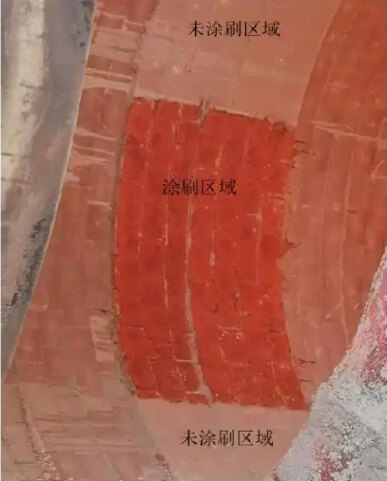

The coating was tested on-site at a steel plant, with magnesia-carbon bricks in the slag line of the ladle selected for application. The appearance of the magnesia-carbon bricks in the slag line was observed after the ladle baking process (the entire baking time was 24 hours). The residual thickness of the coated portion was measured after the ladle was removed from the production line, and compared with the residual thickness of the uncoated magnesia-carbon bricks in the same operating environment as the coated portion. The results are shown in Figures 3 and 4.

Analysis indicates that during the baking process of newly constructed ladles, when temperatures exceed 800°C, the graphite and resin in magnesium-carbon bricks oxidize rapidly. As oxidation progresses, the oxidized sections provide some protective effect to the unoxidized areas, thereby slowing the oxidation rate during the latter stages of baking. The entire baking process results in a complete decarburization layer of approximately 20 mm on the magnesium-carbon bricks. This decarburized layer is characterized by negligible bonding strength, high porosity, and a loose structure. When molten steel is poured, the layer rapidly disintegrates under the erosion and abrasion from the steel and slag, rendering this portion of the lining material essentially wasted.Typically, the working lining thickness of a newly lined ladle is around 200mm. After production runs, the residual working lining is generally about 60mm. Subtracting the oxidized 20mm layer, the effective working thickness is approximately 120mm. The oxidized portion accounts for roughly 15% of the effective usable thickness. Applying anti-oxidation coatings can increase the effective usable thickness of magnesium-carbon bricks by approximately 20mm compared to the original thickness, effectively extending the lining’s service life by about 15%.

Conclusion

(1) The novel anti-oxidation coating exhibits excellent anti-oxidation effects on the resin and graphite in magnesia-carbon bricks at temperatures up to 1100 ℃, resulting in virtually zero loose and decarburized layers.

(2) On-site application effectively prevents oxidation of carbonaceous materials during ladle baking, increasing the effective thickness and service life of these materials and significantly reducing the consumption per ton of steel refractory material in the ladle.

(3) This novel anti-oxidation coating is also suitable for preventing oxidation of other carbonaceous working linings in the ladle during baking.